You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few new knives I've made

- Thread starter willyd6869

- Start date

The Best online firearms community in Louisiana.

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

willyd6869

Well-Known Member

SpeedRacer

Well-Known Member

Very nice

willyd6869

Well-Known Member

Thanks for the compliments guys. They are made from 1/8" O1 tool steel. The Razors are 4.25" OAL. The drop point is 6.5" OAL. They are coming in around 60RC with my files that I use to test. I have an 18" even heat kiln on the way and am planning on really getting going. Kitchen knives are something I have been wanting to do for a while.

TomTerrific

Well-Known Member

Nice work!

From a fellow knifemaker they look good! Now for suggestions - Try lots of different designs but a sharp point is something nice to work into a knife. The micarta handles look good but try really playing with your handle designs. Do a knife in 1/8" steel and stay under 1/4" slabs on each side and watch how it feels. Also for handle don't be afraid to shape it more then a rounded over kind of square.

willyd6869

Well-Known Member

willyd6869

Well-Known Member

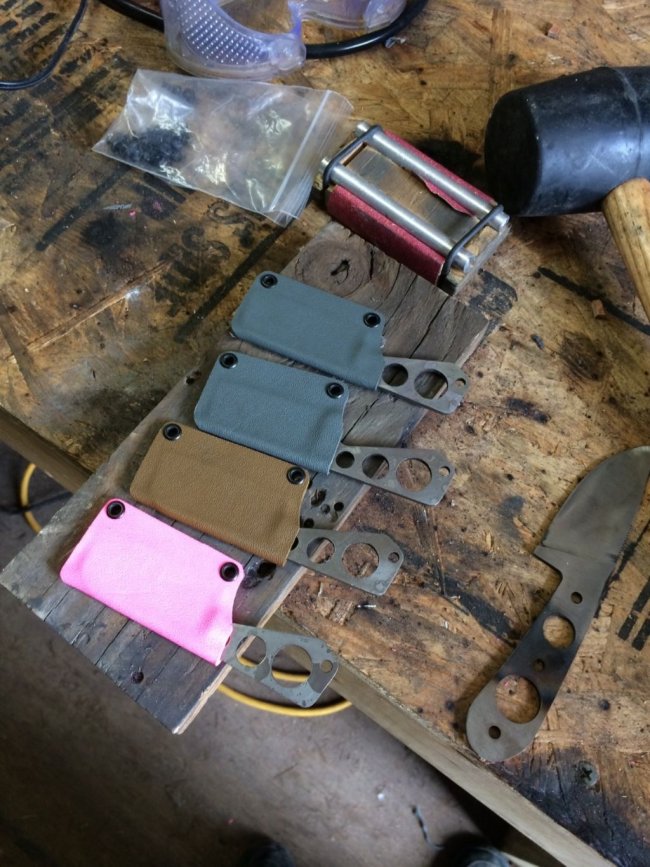

Alrighty, I've got my heat treat recipe down now and am getting around 60 RC, checked by hardness files consistently. I have gone to using jigs instead of free handing and have been getting ridiculously uniform bevels and pre-sharpened edges. For the drop point knives I take them down to 15 thousandths of an inch before sharpening, and the kitchen knife was .007". Here is what I have been making.

Specs:

3" Blade

60 RC

6.25" OAL

Epoxy impregnated paracord handles

1/8" O1 steel

.015" meat behind the edge

Full Flat Grind

Specs:

3" Blade

60 RC

6.25" OAL

Epoxy impregnated paracord handles

1/8" O1 steel

.015" meat behind the edge

Full Flat Grind

Last edited:

willyd6869

Well-Known Member

Specs:

Tanto

4" Blade

7.5" OAL

60 RC

.015" meat behind edge

3/16" O1 steel

Chisel Grind

Santoku

9" Blade

15" OAL

60 RC

.007" meat behind edge

Full Flat Grind

G10 handles with black and pink spacers

This thing is comically sharp. After I made it, I went to open up an avocado and accidentally cut halfway into the pit. It made me laugh out loud.

Tanto

4" Blade

7.5" OAL

60 RC

.015" meat behind edge

3/16" O1 steel

Chisel Grind

Santoku

9" Blade

15" OAL

60 RC

.007" meat behind edge

Full Flat Grind

G10 handles with black and pink spacers

This thing is comically sharp. After I made it, I went to open up an avocado and accidentally cut halfway into the pit. It made me laugh out loud.

Last edited:

The Santoku style kitchen knife looks great! Your handle work looks very well done and your finishing also looks very good! Keep it up!

Staff online

-

340six-Global Mod-

-

thperez1972ESSAYONS

Members online

- Young Gun

- Jiggy205

- dantheman

- Drake

- twinin

- lsufan1971

- folivier

- hotbiggun

- Cledus1911

- 340six

- neverknowsbest

- WhereIsIt?

- Magdump

- Huntingman7799

- xring100

- kpm

- T-boy

- Amoreno468

- Big H

- thperez1972

- GrassRoots22

- Texan1894

- rm2092

- BDill

- Dill

- bushwacker975

- BOSS351

- UncleBiff

- lashooter68

- BOSS302

- jdavid1

- Camoranger2006

- Ranslem9849

- nlognion93

- jcomar1

- TheMole68

- rcourv7

- satoups

- Mr_dees

- Tboy

- bulldog

- tso

- theway109

- highstandard40

- do2gomike

- larryp44

- dontshootmebrah

- k0k0m0

- Mac204

- petingrass

Total: 519 (members: 78, guests: 441)