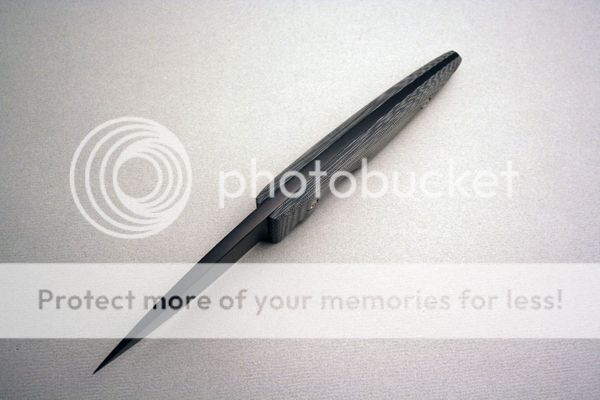

I've forged a few blades and attempted to finish/file/polish by hand, decided that was too much work for my bad hands. Figured I'd try cutting out profile and grinding. After a pile of trial and error, came up with two that deserved to be finished.

Blades are 1/4" 5160, flat grind, taper tang with micarta handles. Still working on the tempering, taking the grinding rejects and trying different temps and then abusing them to see how they hold up. Friend hacked a 2x4 with a previous knife and it kept its edge, a few others snapped in half. These have stayed sharp so far, still have not really pushed to see how they hold up.

Debating fully polishing the blades or going with some sort of secondary finish/treatment; gun bluing, ceracoat, etc...

In process of building a better grinder so I can try some hollow grinds. Also, once the semester is over going to try and forge some damascus billets and give those a try.

Blades are 1/4" 5160, flat grind, taper tang with micarta handles. Still working on the tempering, taking the grinding rejects and trying different temps and then abusing them to see how they hold up. Friend hacked a 2x4 with a previous knife and it kept its edge, a few others snapped in half. These have stayed sharp so far, still have not really pushed to see how they hold up.

Debating fully polishing the blades or going with some sort of secondary finish/treatment; gun bluing, ceracoat, etc...

In process of building a better grinder so I can try some hollow grinds. Also, once the semester is over going to try and forge some damascus billets and give those a try.

Last edited: