DaSouthernYankee

Well-Known Member

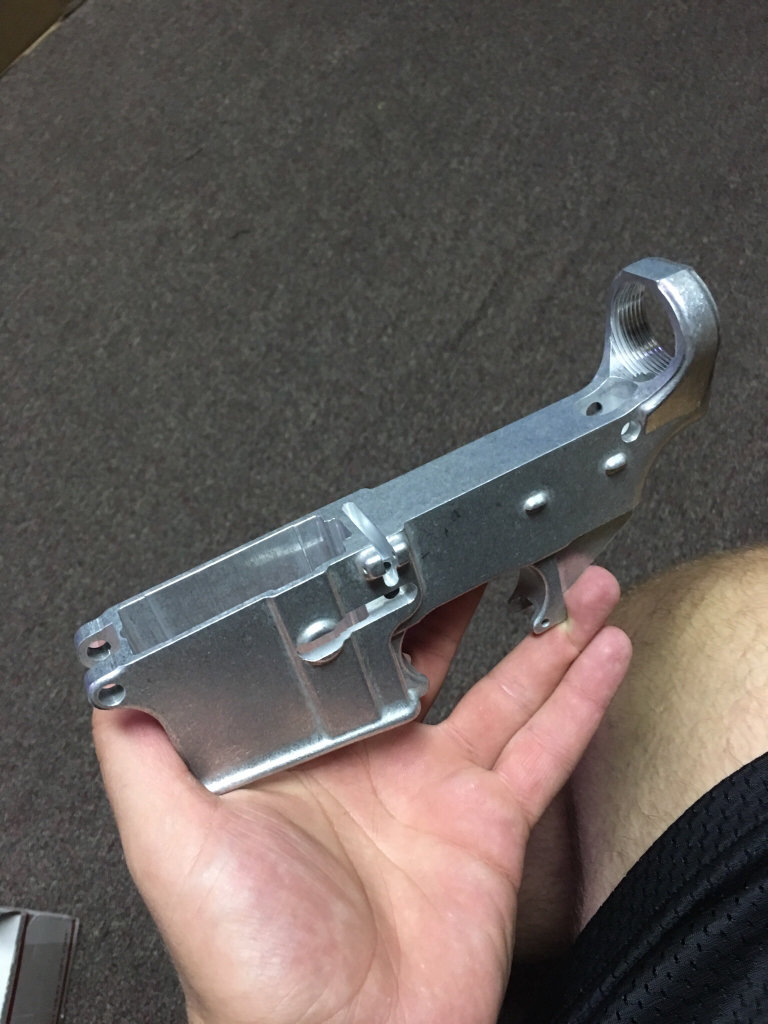

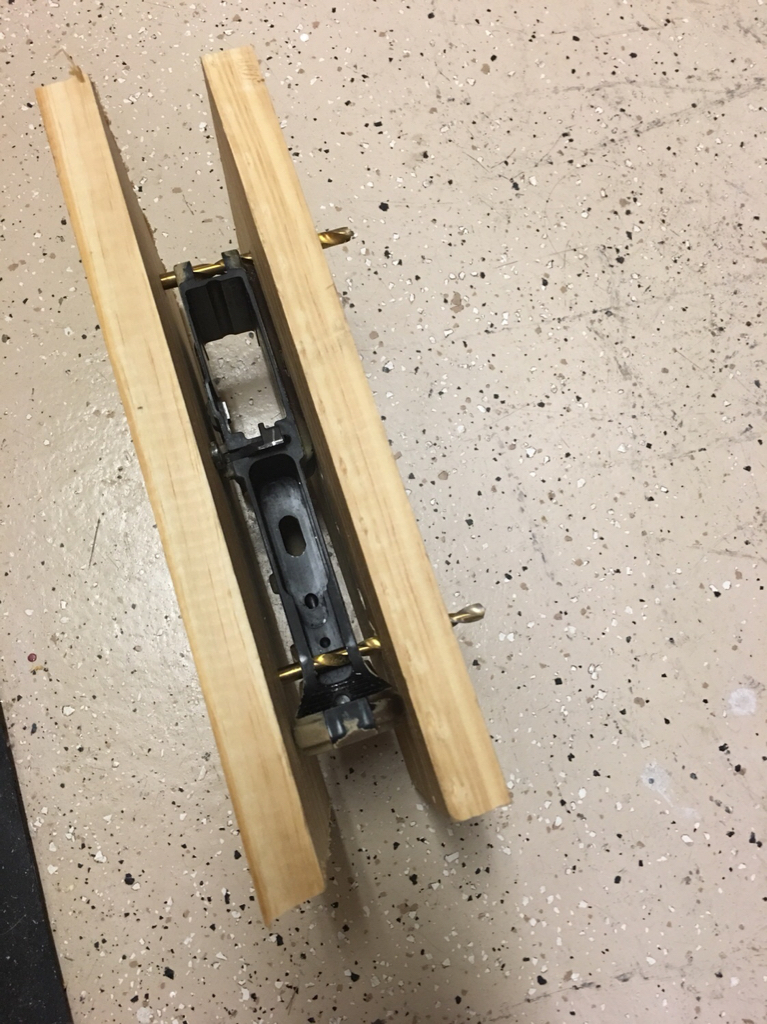

Quick question to y'all here, anyone done it? Any tips for the noob? I decided to look into it some last night and saw EP Armory has a jig and lower on sale for $40 each (aluminum, not polymer). Considering picking one of each up to play with since just ordering a lower or buying one local would be the same or more with FFL fee and sales tax.

Sent from an unidentified bayou mobile device

Sent from an unidentified bayou mobile device