This SOB won’t budge. It’s not staked but possibly a result from loctite from the factory. I have it in a vise and utilizing a proper armorers wrench and nothing. I’m almost to the point of hitting it with a torch to loosen up the presumed loctite but a little nervous as this is a NFA lower and don’t wanna bugger anything up. Any thoughts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Frozen Castle Nut

- Thread starter local2fed

- Start date

The Best online firearms community in Louisiana.

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

leadslinger972

*Banned*

This SOB won’t budge. It’s not staked but possibly a result from loctite from the factory. I have it in a vise and utilizing a proper armorers wrench and nothing. I’m almost to the point of hitting it with a torch to loosen up the presumed loctite but a little nervous as this is a NFA lower and don’t wanna bugger anything up. Any thoughts?

No reputable manufacturers put loctite on the thread of the castle nut & receiver extension. If you're concerned with damaging the lower, I suggest you look into Geissele's Reaction Block.

Do not bother heating it. With a reaction block and a breaker bar, it WILL come loose.

Bigchillin83

Well-Known Member

Heat has worked in locktitght for me, Even a blow drier, aluminum expand very fast and easy, simply heat up castle nut and pour cold water in buffer tube, will cause castle but to expand and buffer tube to shrink, and also loosen up the lock tite with the heat....

Last edited:

Ar you sure its not staked in place? They get pretty clever with it! lol... Use a good lower vise block and a QUALITY buffer tube wrench tool with some leverage. If not feel free to stop by Gretna Gun. We can check it out for you.

dk.easterly

Well-Known Member

If it absolutely won't budge, cut the castle nut.

If it absolutely won't budge, cut the castle nut.

That's what we do in the AK world.

leadslinger972

*Banned*

Cutting it always works lol

Stakes are easily broken off, so it may be on there with some form of threadlocker. I've even heard of (stupid) people putting rockset on the receiver extension threads going into the lower.

Stakes are easily broken off, so it may be on there with some form of threadlocker. I've even heard of (stupid) people putting rockset on the receiver extension threads going into the lower.

leadslinger972

*Banned*

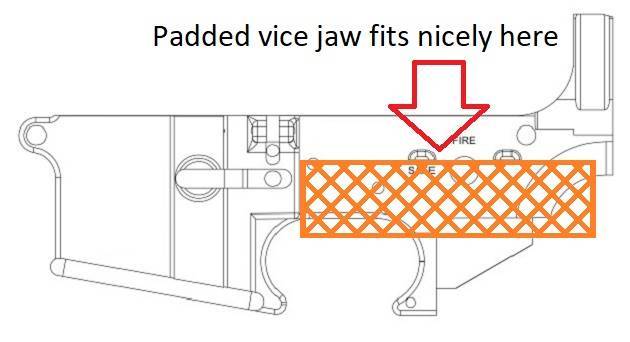

I forgot to ask? What you are clamping in the vise? The lower on a magwell block or the receiver extension?

If you don't want to harm the lower, you need to clamp the receiver extension in a vise.

If you don't want to harm the lower, you need to clamp the receiver extension in a vise.

I love this thread as we have all been there at some point or another, everytime I come out out of the shop my wife ask if I broke anything and what's the $ amount to fix it haha

Sent from my SAMSUNG-SM-G930A using Tapatalk

Sent from my SAMSUNG-SM-G930A using Tapatalk

leadslinger972

*Banned*

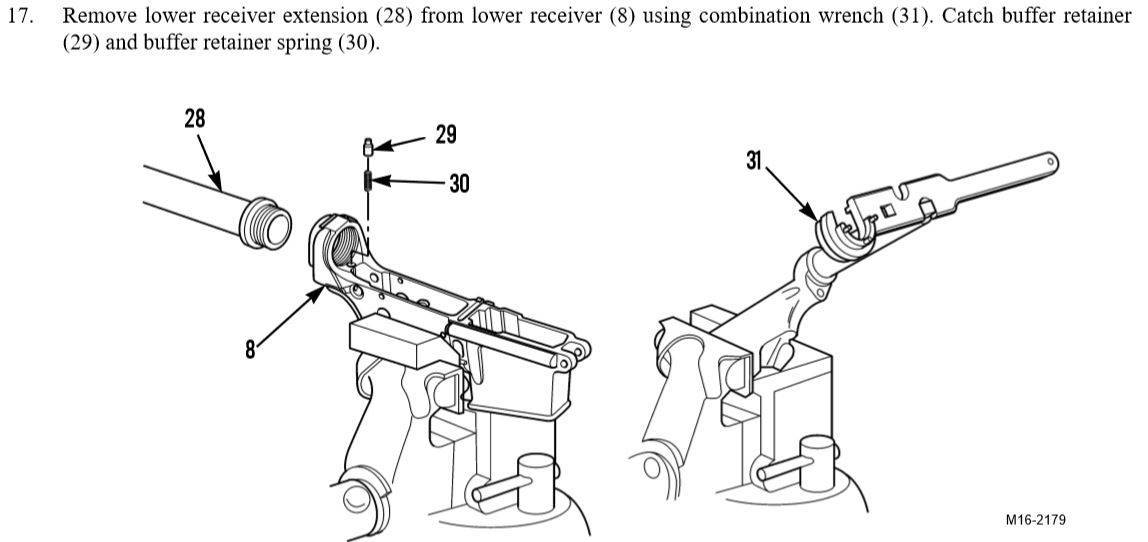

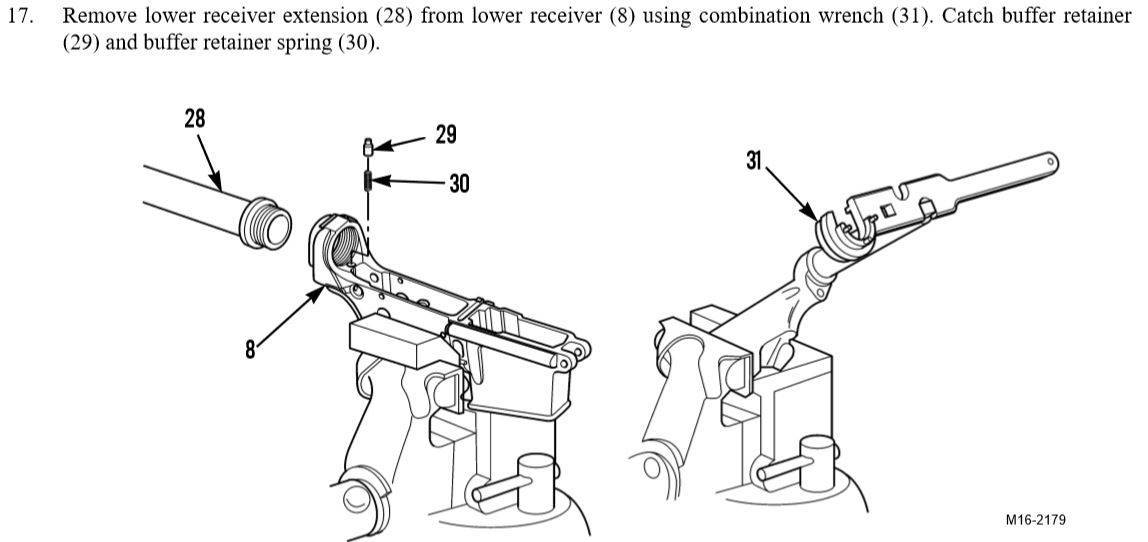

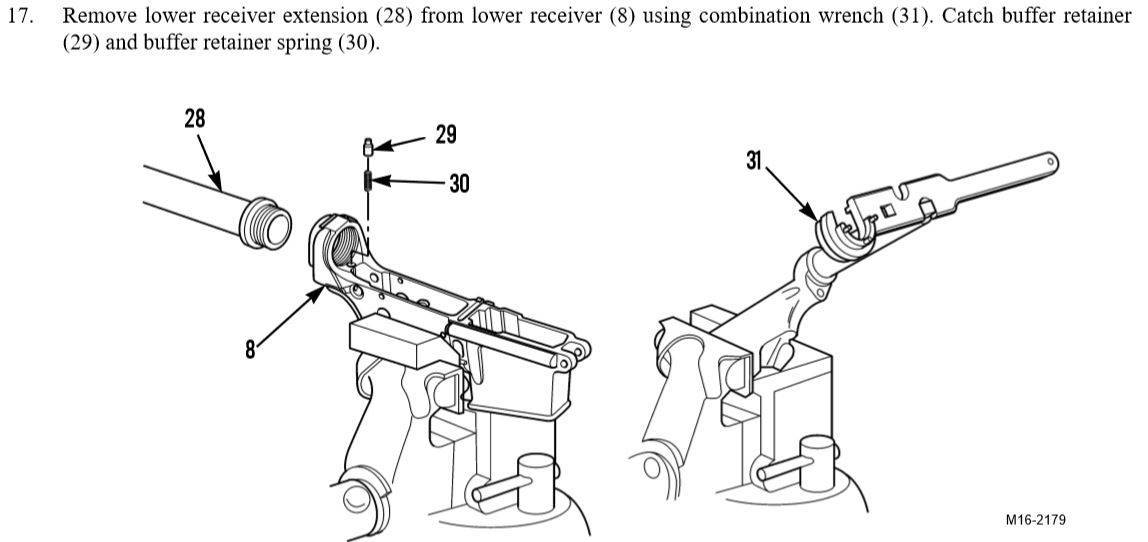

Here is how I do it. It's also the way the TM shows to do it.

Clamping the receiver creates unnecessary torque on the lower, end plate, & receiver extension.

DO NOT DO THIS.

You're trying to loosen a nut on the RECEIVER EXTENSION, so clamp the receiver extension. As someone who works in engineering and design, and someone who recognizes Bill Geissele as an educated engineer, you should absolutely take that into consideration when suggesting "just clamp it here, because the vise jaws fit."

leadslinger972

*Banned*

I love this thread as we have all been there at some point or another, everytime I come out out of the shop my wife ask if I broke anything and what's the $ amount to fix it haha

Sent from my SAMSUNG-SM-G930A using Tapatalk

This +1,000,000,000

Buy the correct tools and don't break anything from the start.

It takes twice as long to half ass something, then rework everything after that fact, as it does to do it right the first time.

Geissele's tool is great, if you have it.

There is nothing wrong with holding the receiver this way. As I stated, this is how it is done per the USMC Technical Manual.

Provide me with a stress analysis and load at which the receiver will yield.

There is nothing wrong with holding the receiver this way. As I stated, this is how it is done per the USMC Technical Manual.

Provide me with a stress analysis and load at which the receiver will yield.

Geissele's tool is great, if you have it.

There is nothing wrong with holding the receiver this way. As I stated, this is how it is done per the USMC Technical Manual.

Provide me with a stress analysis and load at which the receiver will yield.

Your picture does not appear to show the removal or installation of the castle nut. It shows an extension being screwed into the lower. In your picture, one of the two items directly affected by the action is being secured in the vice. In this thread, the OP is not having an issue unscrewing the extension. The OP is having an issue with the castle nut. The castle nut screws onto the extension, not on the lower receiver.

That is the graphic provided in the Technical Manual. I understand that it shows a rifle receiver extension, but it covers both fixed and adjustable stock receiver extensions.

I am fully aware of how it is assembled, and am providing advice backed by a source and experience, not from opinion.

https://info.publicintelligence.net/USMC-M16-MaintenanceManual.pdf

For all I care the OP can crush the extension in a vise and use a pipe wrench on the castle nut, but this oughta be a little easier.

I am fully aware of how it is assembled, and am providing advice backed by a source and experience, not from opinion.

https://info.publicintelligence.net/USMC-M16-MaintenanceManual.pdf

For all I care the OP can crush the extension in a vise and use a pipe wrench on the castle nut, but this oughta be a little easier.

leadslinger972

*Banned*

Geissele's tool is great, if you have it.

There is nothing wrong with holding the receiver this way. As I stated, this is how it is done per the USMC Technical Manual.

Provide me with a stress analysis and load at which the receiver will yield.

Congrats, you just posted a diagram of a rifle receiver extension. For those unfamiliar with a rifle receiver extension, it does not utilize a castle nut nor does it use an end plate. Its torque spec is much lower than what is often used on castle nuts in the commercial market. You also won't find as many rifle receiver extensions being installed with threadlocker as you will find castle nuts installed on carbine receiver extensions.

Yes, asking me for a stress analysis was witty. Good for you. If you were educated, you would be agreeing with me. When you loosen a nut, you hold the bolt, but when you loosen a castle nut, you want to hold the receiver? That makes zero sense.

Before you go off on a tangent about "that's how the USMC" does it, it doesn't mean there isn't a better way. Restraining the receiver extension while loosening the castle nut puts far less strain on the lower than restraining the lower receiver to loosen it. That's pure physics. Arguing with that would show ignorance.

Bill Geissele didn't create the reaction block, because he was bored.

Last edited:

I understand that holding the receiver extension is better, and if the OP has a reaction block, by all means use it.

What I'm saying is:

The receiver is robust enough to handle the force required to remove the castle nut from the receiver extension.

If you suspect that thread locker has been applied to the threads or castle nut, supply sufficient heat to burn it off while not overheating the surrounding material.

The lower receiver is a forged piece of aluminum, it isn't exactly fragile and can take some force.

I have not seen a whole lot of photos of warped or broken receivers from extension removal.

What I'm saying is:

The receiver is robust enough to handle the force required to remove the castle nut from the receiver extension.

If you suspect that thread locker has been applied to the threads or castle nut, supply sufficient heat to burn it off while not overheating the surrounding material.

The lower receiver is a forged piece of aluminum, it isn't exactly fragile and can take some force.

I have not seen a whole lot of photos of warped or broken receivers from extension removal.

leadslinger972

*Banned*

I understand that holding the receiver extension is better, and if the OP has a reaction block, by all means use it.

What I'm saying is:

The receiver is robust enough to handle the force required to remove the castle nut from the receiver extension.

If you suspect that thread locker has been applied to the threads or castle nut, supply sufficient heat to burn it off while not overheating the surrounding material.

The lower receiver is a forged piece of aluminum, it isn't exactly fragile and can take some force.

I have not seen a whole lot of photos of warped or broken receivers from extension removal.

You don't need a reaction block to hold the receiver extension. Vise jaws and a strip of leather works well.

"The receiver is robust enough to handle the force required to remove the castle nut from the receiver extension."

Interesting statement. If it is recommended to install it around 40 ft/lbs, but it was actually installed around 60 ft/lbs with thread locker, the receiver probably won't handle that. He's trying to remove a castle nut that won't budge, not install one.

You may not have seen a lot of photos, but I have.

Last edited:

Staff online

-

thperez1972ESSAYONS

Members online

- thperez1972

- WhereIsIt?

- Tacobellgrande

- BIGBORE44

- jpso211

- SwampyDog

- g45

- cjt0311

- Daspy

- EightySix

- bricklayer

- Tigerbend225

- Arbiterk

- Major

- J. W. Harris

- Bigboi

- speedfreek

- twinin

- ONTARGET7.62

- Nolastorm

- proplaya

- Aurellevi

- Jiggy205

- Bigchillin83

- Savedbygrace

- rcourv7

- BLACKHAWK240

- Kuhndog

- SouthernInsanity

- Musicmasterd12

- Redstik

- UncleBiff

- scooterj

- Magdump

- hotbiggun

- pdugas

- puritanize

- bigsk

- John913

- GearFondler

- Sainte70

- Slim

- d.rayphelps

- BlueShamu

- TLBR

- Rodog

- xring100

- larryp44

- OuttaLine22

- Barcelona

Total: 907 (members: 68, guests: 839)