whbonney26

Well-Known Member

I am looking for someone who can make something out of aluminum. Preferably on the north shore... Slidell- Hammond bit will consider a little further if need be.

I basically need a piece of 1/4* aluminum that is 8 5/8* round and another that is 8 3/4* round which will act as a lip on the first one when cemented together.

Or could be made out of one solid piece if someone has a CNC machine.

It’s a very simple very straight forward design. I just don’t habe to stuff to do it.

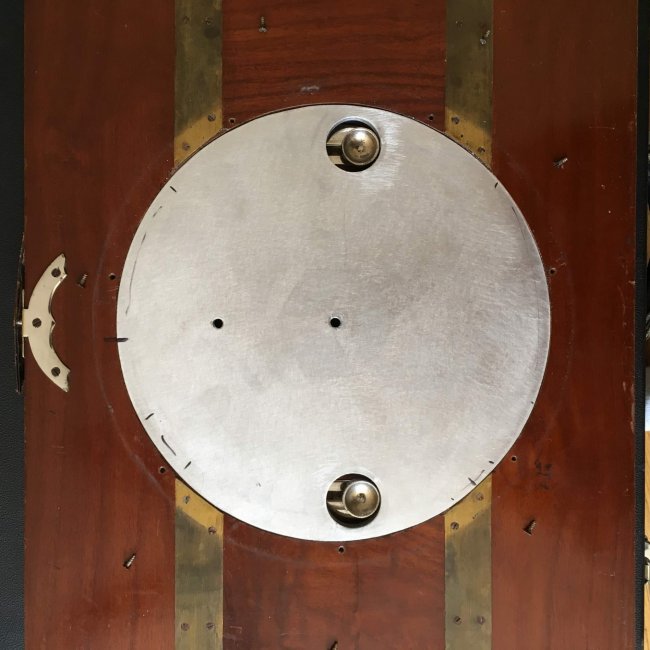

Here are a few pics of what I’m looking for.

I just need it to be solid. I’ll cut the smaller holes and drill and tap the center.

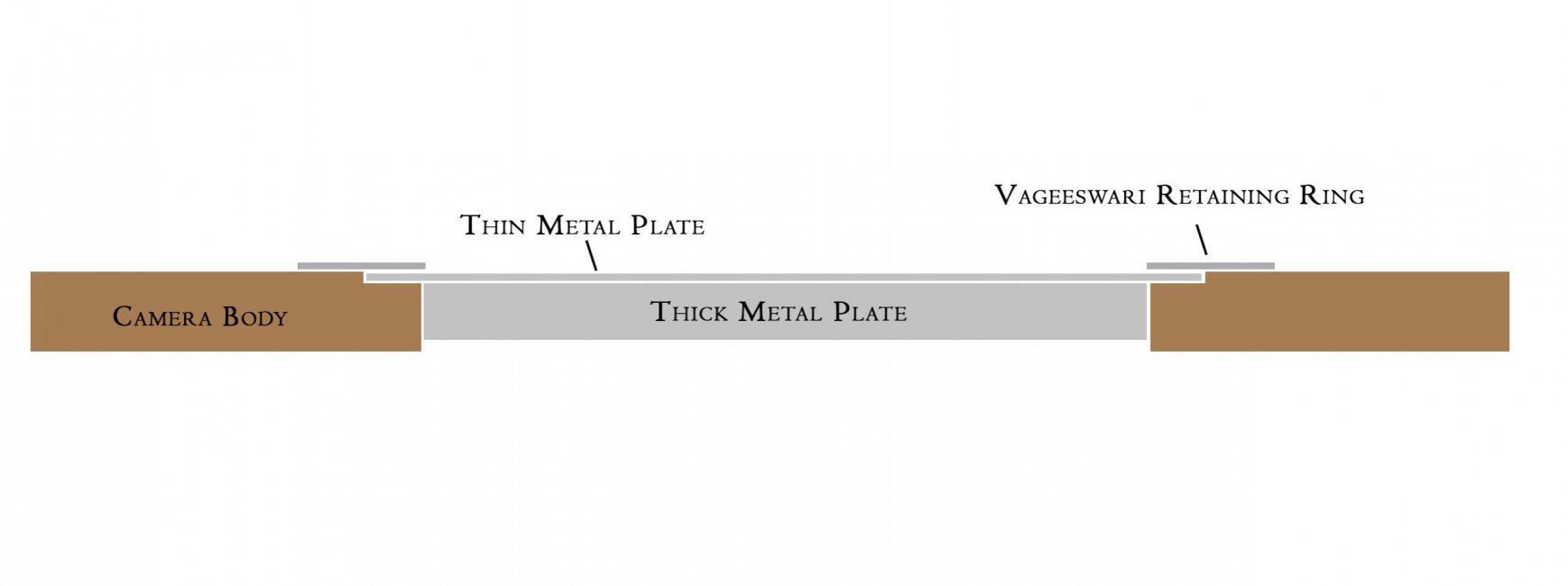

The second photo is a diagram to see what I’m looking for.

I basically need a piece of 1/4* aluminum that is 8 5/8* round and another that is 8 3/4* round which will act as a lip on the first one when cemented together.

Or could be made out of one solid piece if someone has a CNC machine.

It’s a very simple very straight forward design. I just don’t habe to stuff to do it.

Here are a few pics of what I’m looking for.

I just need it to be solid. I’ll cut the smaller holes and drill and tap the center.

The second photo is a diagram to see what I’m looking for.

Attachments

Last edited: