So my MP5 22 SD has the collapsible stock on it which is cool, but has terrible cheek weld due to nothing but the two rods sliding back for you to rest your cheek on. So in my head I dreamed up something I might be able to fashion out of a hard block of foam, then either coat it with epoxy of use it to has a pattern and use a harder material. Mind you my sever lack of engineering skills dictates simple methods and easy materials to work so if it looks a little bit like a 3rd grader do it, that might be a compliment. lol I want something I can slip in between the rod of the stock and snap it in place and have a nice comfortable rounded top to allow a good cheek weld. I managed to go into Hobby Lobby (against my better judgement and wife spending $50) I managed to find a $2.99 block of hard foam to use. After about an hour and half I managed to come up with this basic shape to get the results I was looking for. I think I will try and coat this prototype with some clear epoxy and see how it does. If there need to be changes or I feel like scrapping it, no big deal. I would love to get something like this made using a 3D printer, but if it will cost alot I'll be happy using what I got. I don't know of anybody or local company that has such a thing so really I'm just stuck with this for now. Comments, suggestions.....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HK stock project

- Thread starter Bam Bam

- Start date

The Best online firearms community in Louisiana.

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

It wouldn't cost a lot in materials to 3d print something like that. The cost would be the time to model in in some cad program so the printer knows what to print. Can you take a picture from the bottom of the foam on the rails? What is the distance between the insides of the rails? What is the height of the top of the foam above the rails?

Richard Michael

Well-Known Member

You may be able to use pieces of cardboard to create a form, then epoxy would be able to become infused between the layers.

I'll take the measurements tonight and let you know, thanks.It wouldn't cost a lot in materials to 3d print something like that. The cost would be the time to model in in some cad program so the printer knows what to print. Can you take a picture from the bottom of the foam on the rails? What is the distance between the insides of the rails? What is the height of the top of the foam above the rails?

I'll take the measurements tonight and let you know, thanks.

And the length from front to back.

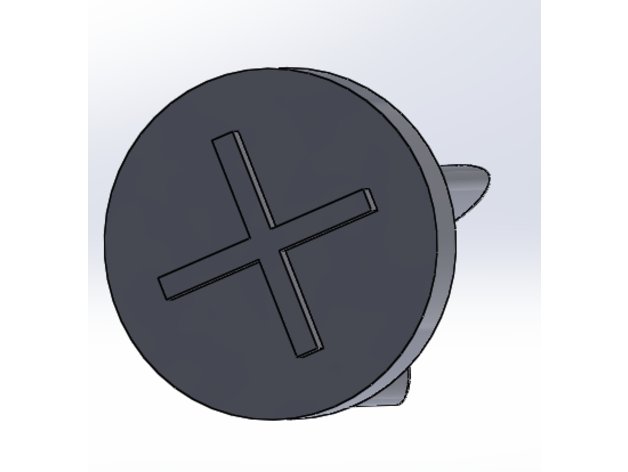

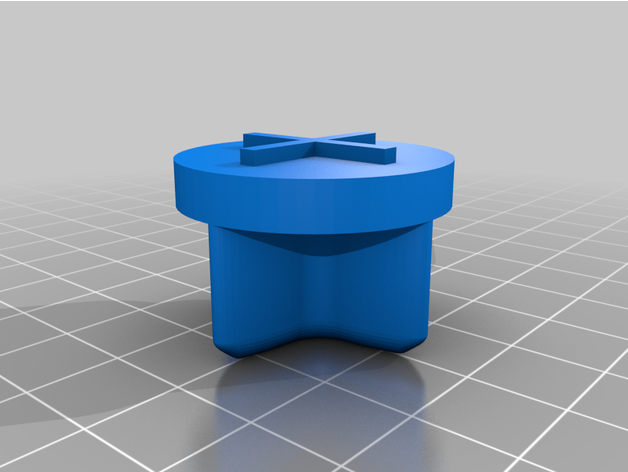

Here's an idea of what could be 3d printed.

That looks perfect! I'll PM tonight. Thanks

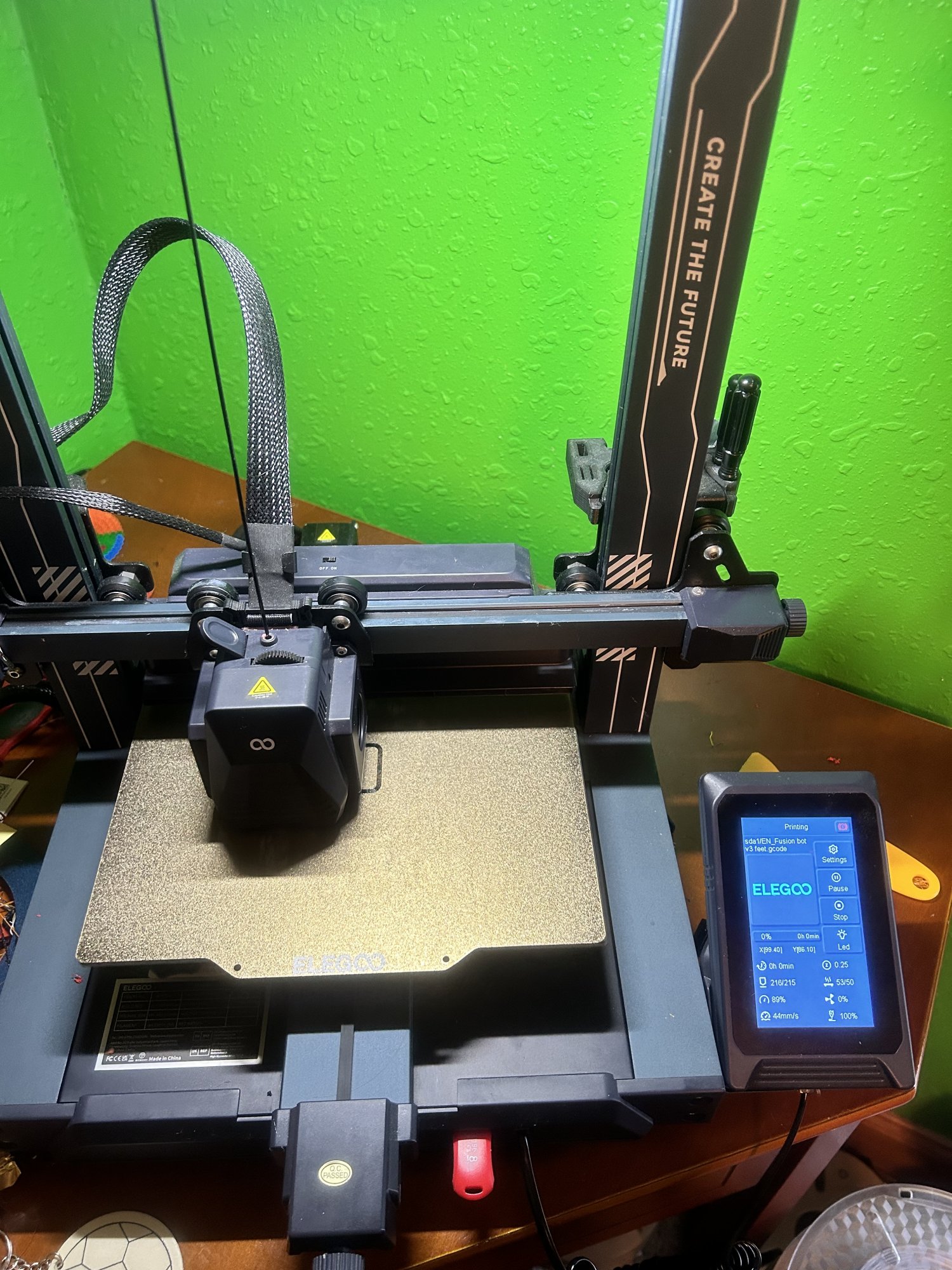

I have an endor 3. It's a good entry level printer that meets my amateur needs just fine. That piece can be extra fast printed in about 2.5 hours. That's usually good enough for prototyping. The final print would take about 7 hours. It's about $25 per kg of filament. The extra fast print uses about 70g and the final print about 150g. No the cost of materials is, in my opinion, negligible. If you know someone with a 3d printer, I can always get you the stl or 3mf file and it can be printed closer to you. I play with fusion 360 a lot designing things for my need so this design was not difficult for me. It probably took me 20 minutes or so. And it's designed with variables. I can plug in the numbers you give me and the design will adjust accordingly. But all that comes from experiences with the software. I like to think of myself as a pretty good novice.

I use to work @ a machine shop right out of High School and learned to love this type of work. We didn't have the modern CNC machine we see today, but still loved it. Sadly I'm NOT a good fabricator or engineer so I'm trying to figure out a way for it to snap in or mount in easily. Is the material pretty sturdy once it's printed?

Bigchillin83

Well-Known Member

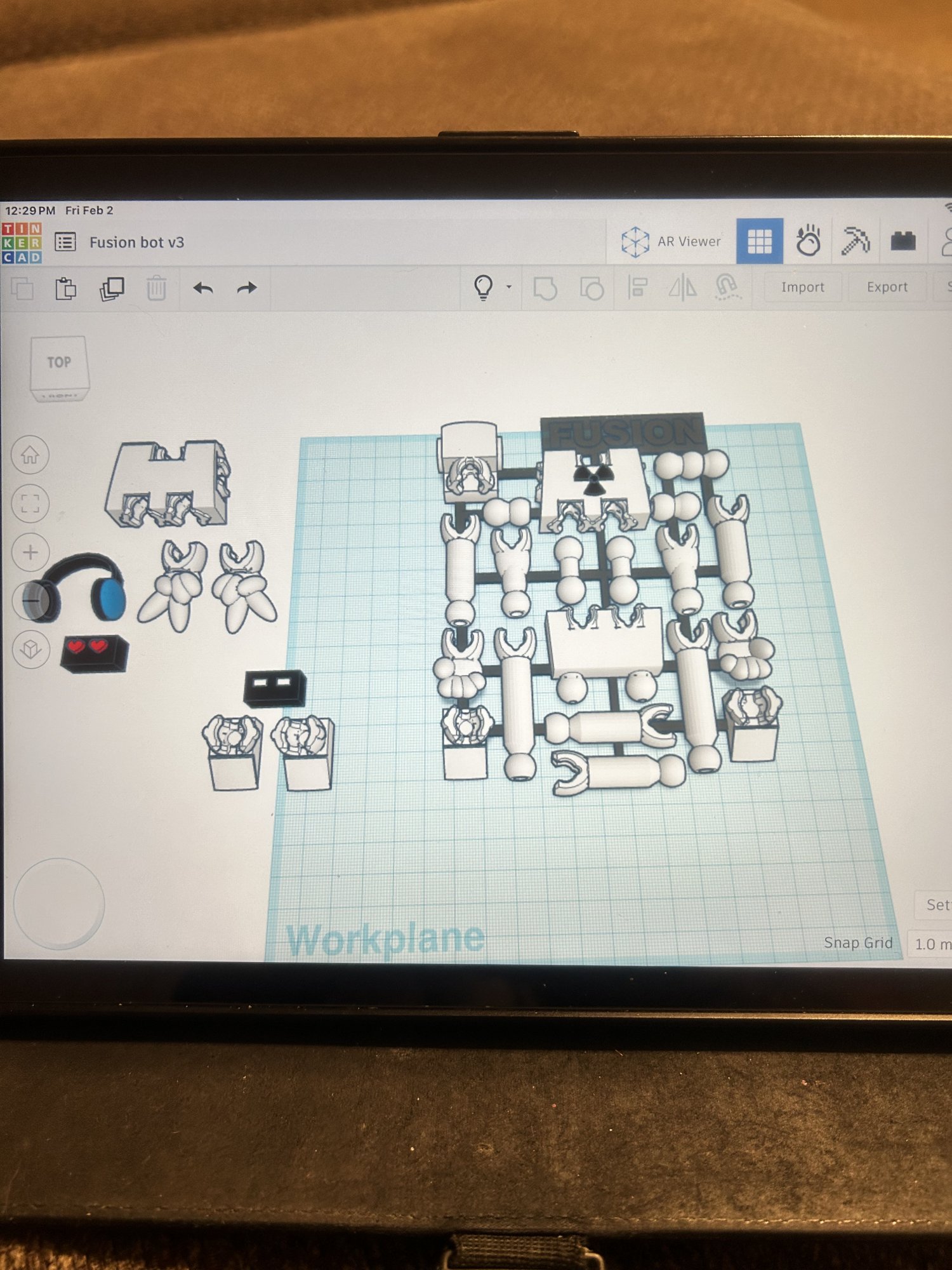

My 15 year old son has a pretty nice 3d printer and designs a god bit, I’ll have to ask him about it, if it don’t work out between yall 2…. Here’s some of the things he’s designed and printed

Some are still a work in progress lol,

Some are still a work in progress lol,

Last edited:

Bigchillin83

Well-Known Member

Edc tray, few more Toys and a sro battery cap removal tool for me lol

Wow B/C, thats pretty cool stuff for a kid to do. I feel so dumb now! lol I was never blessed with the engineering gene, my son now is very good with this type of stuff. he obviously didn't get it from me.

Bigchillin83

Well-Known Member

Mine didn’t get it from me either… lol I don’t understand all the computer stuff I struggle with a iPhone .. but I can swap a motor or change a transmission… guess that tells you what time era we grew up in lol…

Edc tray, few more Toys and a sro battery cap removal tool for me lol

I really do not like tinkercad although I know it's some people's favorite. I will not take offense if he wants to take up the project. I can even send a copy of the stl file and he can print it and make any needed improvements if he's like. Livingston is much closer to Denham Springs/Walker than the Gonzales area is.

I got the 3d printer to help out with my holiday light shows. I've printed a few props but now I usually buy the corrugated plastic and use the printer for connectors or standoffs and stuff like that. The show is synced to music and some of the props, like the bulb and the supersize christmas tree, will sing as well.

Bigchillin83

Well-Known Member

No go for it!!! lol I haven’t even talked to him bout it, that’s just some pics I had on my phone, yea he has a few diff programs he “slices with” he says lol…

It’s deff a cool hobby, only thing bout it is he’s got scrap waste printer food all over his room from cleaning his prints lol.

It’s deff a cool hobby, only thing bout it is he’s got scrap waste printer food all over his room from cleaning his prints lol.

Well after a few weeks time and some trial and error thperez1972 hooked me up with a 3D printed removable cheek piece. It is about as perfect as it gets, sits at same height as stock, snaps in/out when needed and color matches great too! Now I can get a good/consistent cheek weld when shooting this thing. Thanks so much thpetez1972 for all the time and effort you put into this.

Attachments

I'm just glad I was finally able to get something that worked.

Members online

- JBP55

- Pouledous

- BSGA

- BIGBORE44

- Savedbygrace

- apso1857

- WilsonCombatant

- CantThinkPastGo

- Forgotten

- jpso211

- Red Stick

- AdvancedLaser

- charlieecho64

- Love2shoot

- Scottm35

- JaylinBurd

- bigdogg873

- machinedrummer

- Pops 1

- highstandard40

- 323MAR

- Bam Bam

- tekkaman_tnt

- Nboazman1

- jerme

- Brballistics

- AndyG

- Bigchillin83

- ewebb10

- usmc-nav

- Richard Michael

- jlw

- ffgillst2

- sawgrass

- ajk3rd

- tommyg7

- DBMJR1

- Bb07

- Rgates

- navops

- PECEMKR

- tmbold

- GentleBen

- N4sir

- catman3516

- Buck1

- Jerikeaux

- MyTFAL

- OtterBob

- Peacemaker

Total: 795 (members: 86, guests: 709)