This was a fun project, ended up being easier than I thought.

A little backstory 1st, as it will likely help with understanding why I did this, etc.

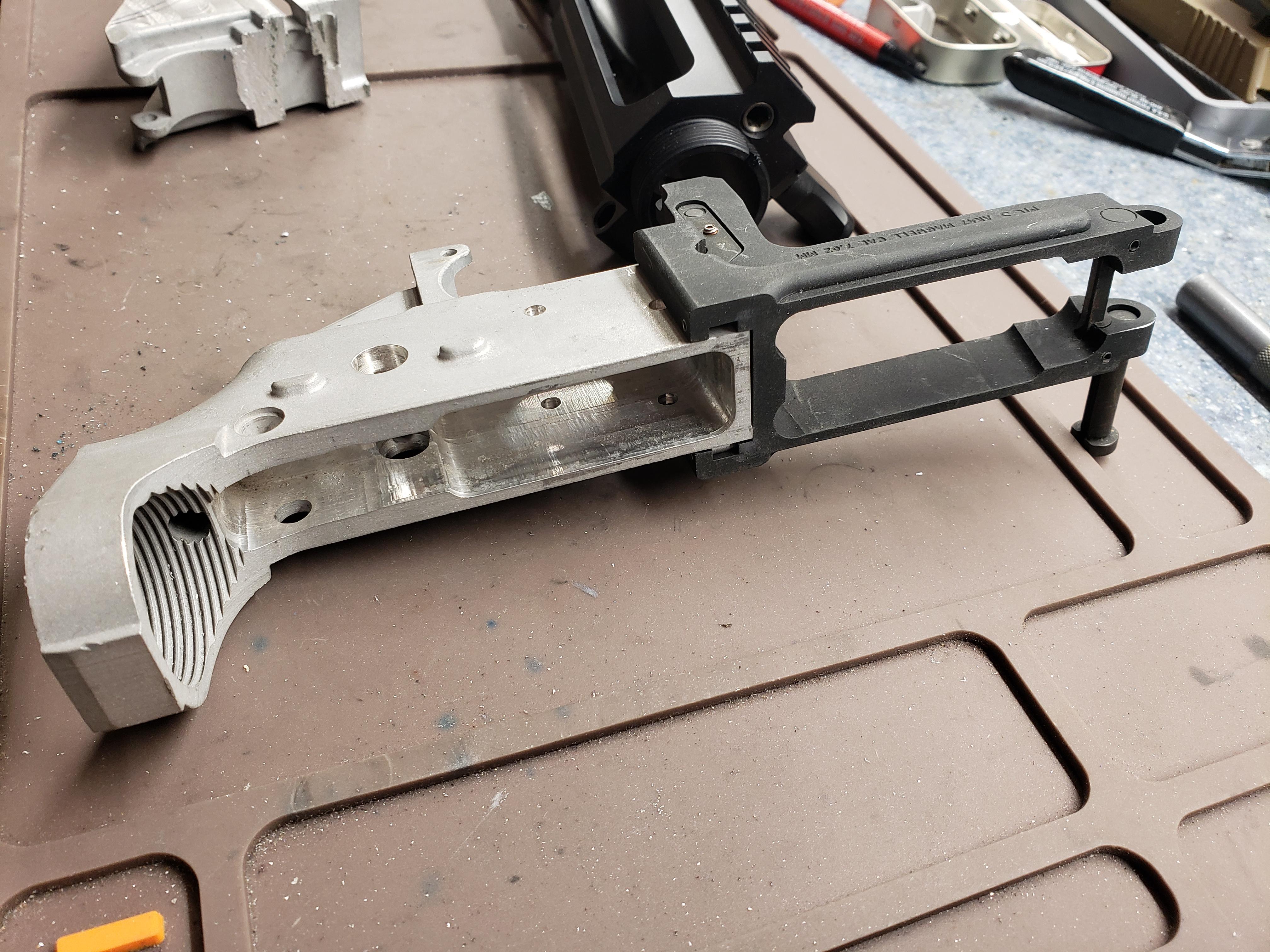

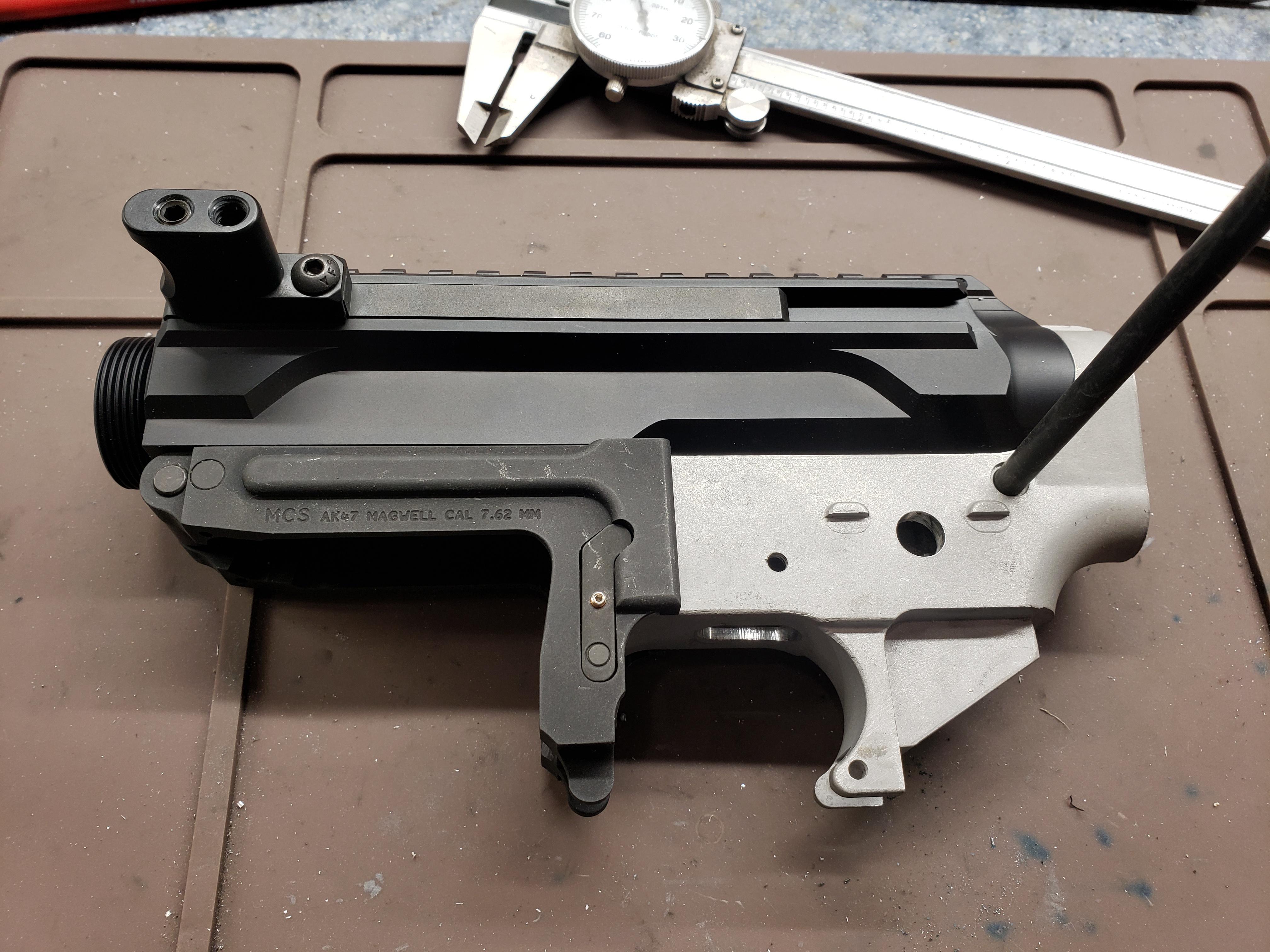

I bought a 7.62x39 AK mag-well from Wyndham Weaponry quite a few years ago. This mag-well is part of their MCS (multi caliber system) AR15 based platform, which is a licensed copy of the MGI Hydra. Basically it is AR15 lower receiver that is made to accept a variety of removable mag-wells to allow for caliber conversion. There is also an upper that allows for tool-less barrel changes, but I do not have that, and honestly do not think that it is anything more than a novelty (and the interchangeable mag-wells is not much different either if I am being honest!). My end goal was a AR in 7.62x39 that fed from AK mags. I like making stuff so the thought of modding an existing AR15 lower to work with the mag-well was appealing and I figured I would likely buy the AR15 magazine and colt 9mm magazine mag-wells at a later date.

Well, that later date came and went, Wyndham is out of business, so no more new mag-wells to buy. And I never did get the correct upper receiver either, which has to be wider at the magazine well area to accommodate an AK magazine, since they are wider across than a std AR15 magazine. So I did some more research, found that Gibbz Arms makes a purpose made upper that will fit the AK mags, has shelves that prevent over insertion, and has a non-reciprocating side charging handle on the left (correct) side of the receiver. That solved many issues, and got my interest back in this project.

On a side note, I also purchased a used, complete, Palmetto KS47 rifle, and a selection of 80 percent AK mag lowers from various companies that had become available since I originally started this project. So now I have multiple options, and the end result of this deep dive is likely beyond the scope of what I am showing here. But I know people like to see stuff built, so here we go. Pics and info to follow.

A little backstory 1st, as it will likely help with understanding why I did this, etc.

I bought a 7.62x39 AK mag-well from Wyndham Weaponry quite a few years ago. This mag-well is part of their MCS (multi caliber system) AR15 based platform, which is a licensed copy of the MGI Hydra. Basically it is AR15 lower receiver that is made to accept a variety of removable mag-wells to allow for caliber conversion. There is also an upper that allows for tool-less barrel changes, but I do not have that, and honestly do not think that it is anything more than a novelty (and the interchangeable mag-wells is not much different either if I am being honest!). My end goal was a AR in 7.62x39 that fed from AK mags. I like making stuff so the thought of modding an existing AR15 lower to work with the mag-well was appealing and I figured I would likely buy the AR15 magazine and colt 9mm magazine mag-wells at a later date.

Well, that later date came and went, Wyndham is out of business, so no more new mag-wells to buy. And I never did get the correct upper receiver either, which has to be wider at the magazine well area to accommodate an AK magazine, since they are wider across than a std AR15 magazine. So I did some more research, found that Gibbz Arms makes a purpose made upper that will fit the AK mags, has shelves that prevent over insertion, and has a non-reciprocating side charging handle on the left (correct) side of the receiver. That solved many issues, and got my interest back in this project.

On a side note, I also purchased a used, complete, Palmetto KS47 rifle, and a selection of 80 percent AK mag lowers from various companies that had become available since I originally started this project. So now I have multiple options, and the end result of this deep dive is likely beyond the scope of what I am showing here. But I know people like to see stuff built, so here we go. Pics and info to follow.